Industrial Applications

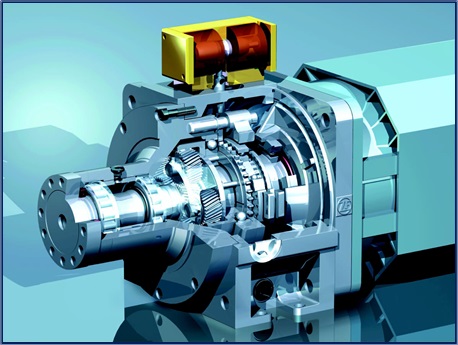

ZF – Duoplan Coaxial Gearboxes

Mechanical gearbox with two speeds

ZF has extended the range of two-speed Duoplan gearboxes, which have already proven their qualities, with a space-saving variant and increased the range of applications with an in-line solution for mounting the gearbox to the machine shaft.

Advantages:

– low vibrations;

– higher revolutions – towards 1200 rpm;

– lower temperatures;

– low noise level;

– reduction of system costs;

– safe operation – no transmission belts;

– the oil bath is no longer necessary, it is guided directly at the lubrication points;

– it can be used for both alternating current and direct current motors;

– they are much more capable of withstanding high radial forces than belt transmissions mounted directly on the motor shaft;

– the same gearbox can be used for several machines.

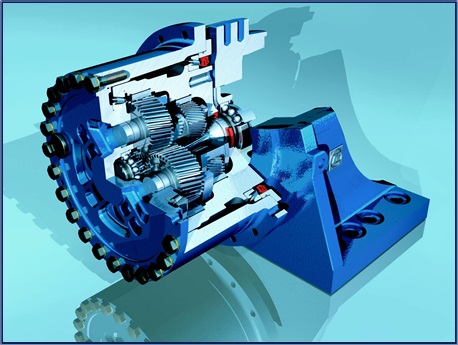

ZF – SERVOPLAN gearboxes

Compact design for precision positioning in automation technology

In many areas of automation technology, the requirements and specifications for transmissions are increasingly demanding.

The standard requirements imposed by the market include:

– small backlash,

– high stiffness,

– low vibration,

– high efficiency,

– low inertia force and minimum idle values, as well as small space.

The gearboxes offer optimized solutions for customer requirements, such as:

– exact positioning (backlash < 1 arc min) with an extremely high efficiency of over 94%;

– the lowest angular precision ensures smooth and silent operation in any

position adjustment.

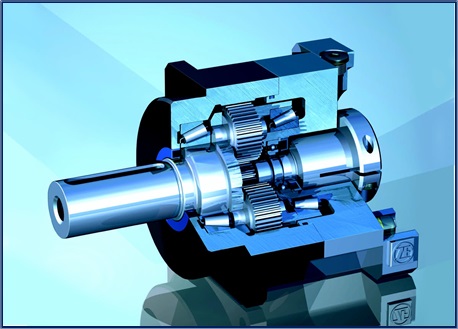

ZF – Servoplan Planetary gearboxes

The Servoplan family is adapted for almost all areas of automation, for example, for exact positioning, in the packaging industry, in the woodworking industry or for machine tool feeding lines.

The Economy series of the ZF – Servoplan planetary gearbox has been designed for direct mounting on servomotors and can be adapted to almost all types of motors.

The driving force is transmitted directly, with little backlash, thus facilitating fast and extremely precise movement sequences.

The output shaft of the servomotor is connected to the center gear of the transmission by means of a sleeve coupling.

The center gear drives three planetary gears inside the planetary carrier, which rotate inside the inner ring guide.

The construction is compact with high energy release density as a result of the equal distribution of force between the three planetary transmissions, and the safety of the performance is partly given by the robust gears.

Features of the ZF Servoplan Economy line:

– ease of mounting on the engine with the help of the modular flange connection system.

– the input guide element ensures proper alignment of the gearbox to the motor shaft, preventing the reduction of bearing life due to incorrect preload.

– great flexibility by using an input coupling system with qualities recognized and proven in practice.

– motor shaft / gearbox connection with a sleeve coupling that ensures a power transmission

without slipping and which does not produce wear.

– integrated axial compensation system along the entire length that absorbs the caloric increase of the motor shaft.

– high efficiency and low noise level during operation due to superior gearing quality, cage-free needle bearings in planetary gearboxes and high quality lubricant.

– high torsional rigidity and high values of the permitted acceleration torques as a result of the robust construction and the optimized geometry of the planetary transmission.

– transmission ratios from i=3 to i=1000.

– maintenance-free operation with consistent grease lubrication throughout its lifetime.

– use in any mounting position.

SERVICE FAUR SRL offers a wide range of products and services with various industrial applications, drilling rigs, railway, automotive, agricultural, naval. We also offer technical assistance, service, schooling, periodic maintenance overhauls, repairs of components and subassemblies, general and capital repairs and execution of spare parts.